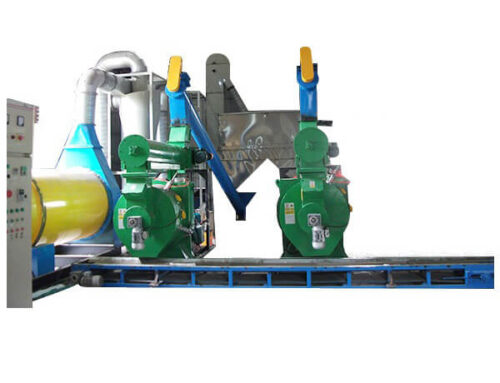

With this 4-5t/h production line, the palm biomass pellets can be produced when the raw materials go through chipping, crushing (or grinding), pelleting, cooling, and packaging. The followings are the brief introductions of the machines adopted in 4-5 t/h palm biomass waste pellet plant.

BX216 Drum Wood Chipper

Wood chipper is used for processing tree limbs or trunks into smaller wood chips. It is mainly composed of base, feed inlet, cutter, body, blade and electronic control. The blades can be adjusted so as to produce chips of different sizes. There are disc wood chipper and drum wood chipper to be chosen. In this production line, we recommend you BX216 drum wood chipper.

Features of BX216 Drum Wood Chipper

1.With a wide application for chipping wood materials and processing biomass materials.

2.With the secondary-feeding system, the drum wood chipper can work more efficiently.

3.With its body made of high-strength steel, is shock resistant and firm.

4.A series of screens is able to meet your requirement for processing wood chips with different sizes.

5.With the hydraulic buffer system, this chipper can be easily maintained.

| Model | BX216 |

| Feeding material size | 230*500mm |

| Blades amount | 2 |

| Roller turning speed | 590rpm |

| Conveyor engine power | 3kw |

| Weight | 4070kg |

| Wood chip size | 30mm |

| Capacity | 7-8t |

| Power of main engine | 55kw |

| Feeding roller engine power | 3-4kw |

| Oil pump engine power | 1.5kw |

| Dimension | 1800*4900*1210mm |

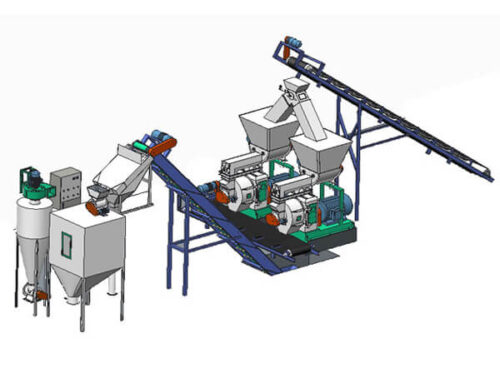

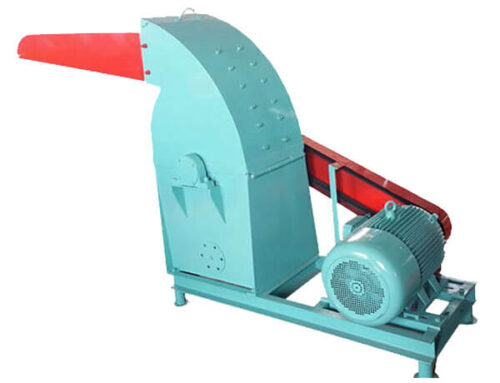

ZW120B Water Drop Hammer Mill

This water drop wood hammer mill is specially developed for large or medium sized wood processing industry. The advantages we choose water drop hammer mill are shown as below.

1. The all-in-one base design makes the structure of the hammer mill steadier.

2. The advanced double-strike technology is adopted for the pulverizing chamber, the pedestal of which is of good rigidity and small vibration.

3. A variety of screens are available to choose.

4. Adopting the flexible opening device and elastic pressure screen mechanism, it is convenient to operate and maintain.

5. The internationally- advanced energy-saving technology is adopted.

| Model | ZW120B |

| Capacity | 4.5-5.5 t/h |

| Rotor diameter | 660mm |

| Main shaft rotate speed | 2980RPM |

| Hammer linear speed | 87m/s |

| Grinding chamber width | 1200mm |

| Hammer quantity | 156 |

| Power | 132/160kw |

| Normal air volume | 130m3/min |

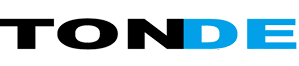

MZLH508 Ring Die Pellet Mill (three sets)

In this production line, three MZLH508 ring die pellet mills shall be adopted to meet the production requirement.

Features

1. With high efficiency, lower power cnsumption and stable operation.

2. With better transmission performance and less noise due to the imported bearings (NSK) & seals (NAK) equipped.

3. With longer service time due to the corrosion-resistant ring die made of stainless steel.

4. Attributing to the permanent magnet device, impurities can be removed during the pelletizing process.

5. The stand-alone oil lubrication system is more effective in maintaining lubrication and keeping the bearings from abrasion.

| Model | MZLH508 |

| Main motor power | 90kw |

| Ring die inner diameter | 508mm |

| Roller outer diameter | 190mm |

| Roller quantity | 2 |

| Capacity | 1.5t/h |

| Screw feeder power | 2.2kw |

| Ring die rotate speed | 150rpm |

| Pellet size | 6mm, 8mm, 10mm etc. |

| Roller working temperature | ≤85℃ |

SKLN4 Pellet Cooler

Features

1. Advanced counter-flow cooling principle is adopted, avoiding surface of the pellet from being cracked.

2. The pellets can be cooled evenly and sufficiently due to the octagon cooling design.

3. Stable operation can be ensured and materials can be reduced due to the equipped reciprocal slide valve.

4. Closed air entry system is adopted to enlarge the area of inlet air, thus ensuring efficient cooing effect and avoiding cross contamination.

5. It consumes less energy and it can be easily operated.

| Model | SKLN4 |

| Cooling volume | 4m3 |

| Power | 1.5kw |

| Production capacity | 3-5t/h |

| Cooling time | ≥6-10min |

| Air lock power | 0.55kw |

WDCS-50 Biomass Pellet Packing Machine

Main features of packing machine

1.With simple structure and flexible operation.

2.Highly automatic and precise in weighting and packing.

3.Easy to assemble, operate, and maintain.

4.With accurate weighing & packing performance.

| Model | WDCS-50 |

| Capacity | 3-4bags/min(5-50kg/bag) |

| Power | 2.2kw |

| Dimension | 2*0.8*2.6m |