Double Paddle Feed Mixer Introduction

Feed mixer has a direct effect on the quality of feed pellets, so it is a key processing equipment in feed pellet plant. This double paddle feed mixer is designed for mixing all kinds of powdery, granular, flaky and block materials. It is a horizontal mixing equipment featured by short mixing time, low energy consumption, high mixing accuracy and customized spray system. This mixing machine can be used for mixing chicken feed, cattle feed, pig feed, fish feed and other livestock or poultry feed. It also has great popularity in food, chemical and fertilizer industries.

Double Paddle Feed Mixer Features

1.Low energy consumption, high mixing speed and short mixing cycle with 30-120s per batch of material.

2.Equipped with air return pipe, which can avoid the dust leakage.

3. High mixing uniformity and none gravity segregation, CV ≤5%.

4. Full base type electric or pneumatic discharging door led to quick discharging and low material residue rate.

5. If it is necessary to add molasses, fat, oils or other liquids, atomized spray system can be exclusively customized.

6. Materials for machine bodies can be chosen from carbon steel, stainless steel and composite materials etc.

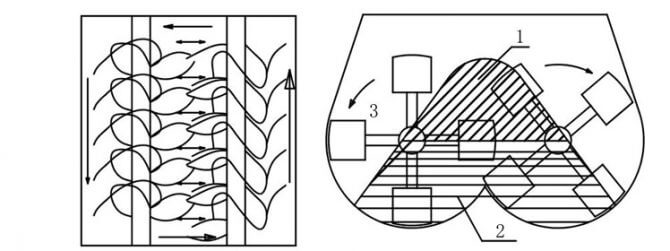

Double Paddle Feed Blender Structure

This double paddle feed mixer is a horizontal mixing machine and the body is w type, it is composed of rotor, transmission body, discharge door, sealing device, discharge control system and adding liquid system.

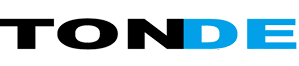

The Working Principle of Double Paddle Feed Mixer

This mixing machine is consist of two opposite rotors with multiple special angle paddles. On one hand, the paddle makes sure that the raw material is counterclockwise rotation along the inner wall of the machine. On the other hand, the paddle let the raw material turn left or right. Then there is a weightless zone between the overlapping region of the two paddles. The raw material can be cycle turned continuously in this weightless zone and be in a homogeneous mixture in a very short time. We can also offer you a atomized spray system to add liquid nutrition for better mixing results.

SSHJ Series double Paddle Mixer Technical Parameters

| Model | SSHJ0.5 | SSHJ1 | SSHJ2 | SSHJ4 | SSHJ6 |

| Effective Volume(m3) | 0.5 | 1 | 2 | 4 | 6 |

| Mixing Volume(kg) | 250 | 500 | 1000 | 2000 | 3000 |

| Mixing Time(s) | 30-120 | 30-120 | 30-120 | 30-120 | 30-120 |

| Mixing Evenness(cv%<) | 5 | 5 | 5 | 5 | 5 |

| Power(kw) | 5.5 | 11 | 18.5 | 30 | 45 |