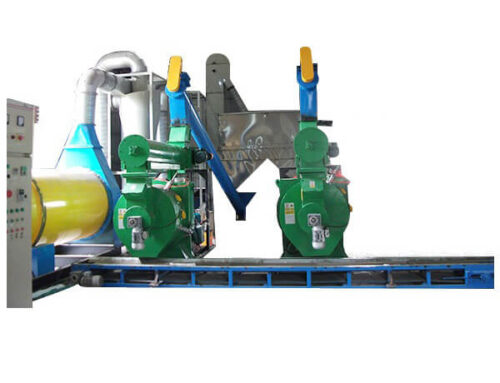

Wood Pellet Weighing & Packing Machine Introduction

Weighing and packing is the last procedure in wood pellet production process, which plays the indispensable role in improving wood pelletizing efficiency. Our automatic weighing & packing machine is consisted of engine body, feeding device, lever system, weighing hopper, electromagnetic counter and pneumatic control unit. All weighing parameters input by the instrument panel, and the feeding speed, clamping bag and loosening bag can be fully automatic controlled. Besides the pellets, it is also applicable to powdery materials.

Wood Pellet Weighing & Packing Machine Features

1. Adopt double-speed motor belt feeding mechanism, it is applicable to wide range of materials.

2. The weighing control instrument is fully digital and intelligent, making high weighing accuracy, fast speed and simple operation.

3. Hopper weighing and reasonable return air structure ensure compact structure, easy installation and reduced dust.

4. Gross weight and net weight can be displayed simultaneously.

5. Automatic taring, zero tracking, detecting and correcting weighing error.

6. Has the function of bag number accumulation, achieving the quantitative management of the production process.

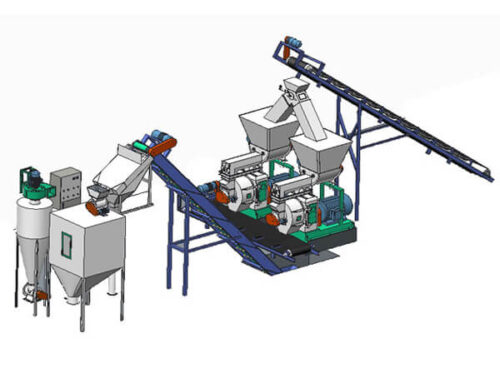

Automatic Weighing & Packing Machine Application

Automatic weighing and packing machine is applicable to quantitative packing of particle materials, spherical materials, strip shaped materials and coarse powder materials in the industries of feed, grain, medicine, cement, oil and chemical, such as cereal, feed pellet, wood pellet, granular fertilizer, salt, traditional Chinese medicine granules, washing powder, etc.

Pellet Weighing and Packing Machine Technical Data

| Model | SDBY-P | SDBY-XP | SDBY-P-D | SDBY-P-W |

| Weighing hopper type | Single hopper | Small measurement | Double hopper | No hopper |

| Weighing range(kg) | 15-50 | 10-20 | 15-50 | 15-50 |

| Weighing speed(bags/min) | 6-8 | 5-7 | 8-12 | 4-6 |

| Power(kw) | 1.1 | 1.1 | 3 | 1.1 |

| Weighing accuracy | Static ≤ ±0.1%, Dynamic ≤ ±0.2% | |||

| Working temperature | -10—40℃ | |||

| Installation height(m) | 3.7 | 3.2 | 3.8 | 2.5 |

Leave A Comment