Olive Pomace as Raw Materials for Fuel Pellets

Olive pomace is the remaining by-product during the olive oil production process and consists of shells, pulp and olive pit fragments. Thanks to its excellent suitability for combustion, olive pomace becomes a superior raw material for fuel pellets. The olive pomace is easy to handle, and the pellets production process is very simple.

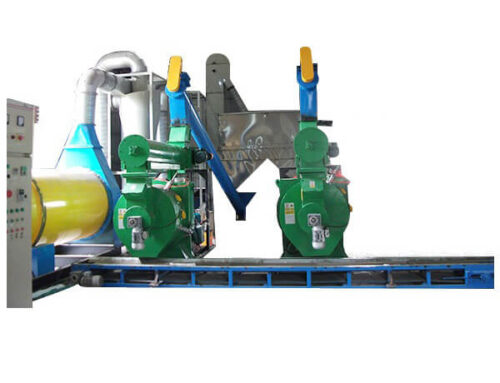

Typical Production Process in Olive Pomace Pellet Plant

After sufficient extraction of olive oil, the olive pomace is in powder form, and the moisture content is around 12%. Therefore, the olive pomace can be pelletized directly. Generally, olive pomace pellet manufacturing process can be divided into pelletizing process, cooling process and packing process.

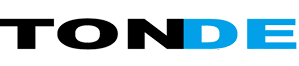

Pelletizing Process

Due to the specific characteristics of olive pomace, it can be made into pellets directly without any further treatment. For a 1.5t/h olive pomace pellet production line, a model 508 ring die pellet machine is needed. It is specially designed for making various biomass materials into wood pellets for industrial and commercial use. The ring die pellet machine can continuously make olive pomace pellets with high efficiency but low noise, low malfunction, and low energy consumption.

Parameters of 508 Ring Die Pellet Machine

| Model | MZLH508 |

| Capacity | 1.5t/h |

| Screw feeder power | 2.2kw |

| Ring die rotate speed | 150rpm |

| Pellet size | 6mm, 8mm, 10mm etc. |

| Roller working temperature | ≤85℃ |

| Main motor power | 90kw |

| Ring die inner diameter | 508mm |

| Roller outer diameter | 190mm |

| Roller quantity | 2 |

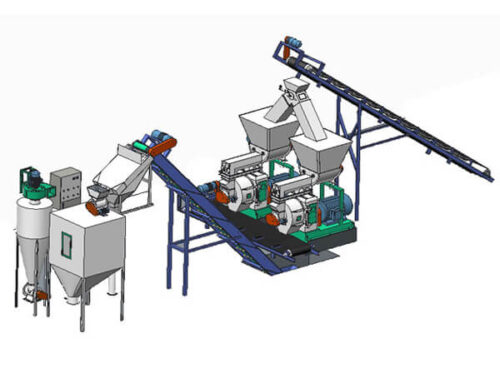

Cooling Process

When olive pomace pellets come out of the pellet mill, they are always hot and wet. Pomace pellets will shock if the temperature or humidity is too high. Counter flow pellet cooler is used here to remove the pomace pellet heat as well as the moisture content to ensure pellets quality and shelf-life. The machine adopts advanced counter flow cooling principle, avoiding the cold air direct contacting with hot pellets, which prevents the surface cracking of pomace pellets.

Pellet Cooler Technical Data

| Model | SKLN1.5 |

| Capacity | 3t/h |

| Power | 0.75kw |

| Cooling volume | 1.5m3 |

| Cooling time | ≥6-10min |

| Air lock power | 1.1kw |

Packing Process

After cooling, the pomace pellets are packaged into bags for the sake of pellet protection and convenient distribution. Automatic pellets packing machine is a advanced designed and manufactured bagging machine, with PLC controlling technology adopted and accurate measure instrument equipped, thus it has high weighing precision, bagging speed and stable performance. The olive pomace pellets can be packed with different specifications based on specific requirements.

Notes: olive pomace pellets should be kept in dry conditions and be stored in tanks, containers, or silos.

Pellet Weighing and Packing Machine Technical Data

| Model | Capacity |

| WDCS-50 | 3-4bags/min(5-50kg/bag) |

| Power | Dimension |

| 2.2kw | 2*0.8*2.6m |

Features of Olive Pomace Pellet Plant

1.Compact structure, only one ring die pellet mill is installed.

2.Simple operation.

3.Easy maintenance.

4.Small location required.

5.Complete installation service and reliable after-sale service and support.