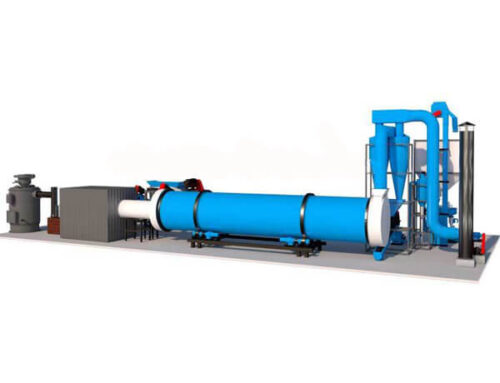

Introduction to Sawdust Pipe Dryer

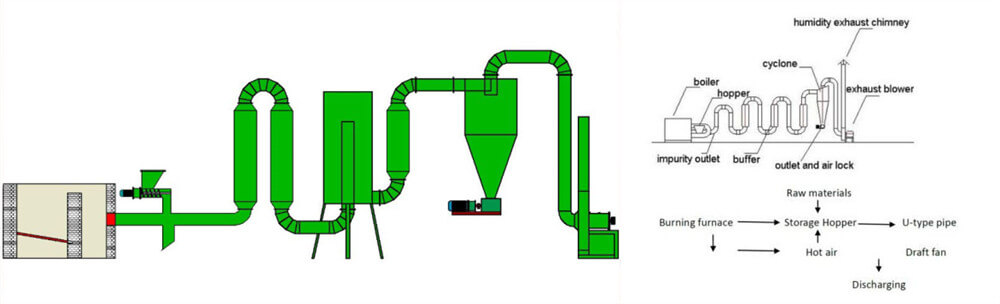

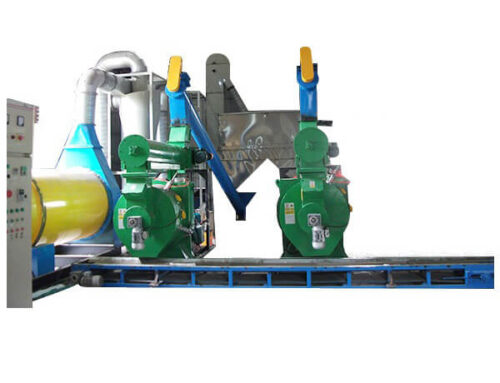

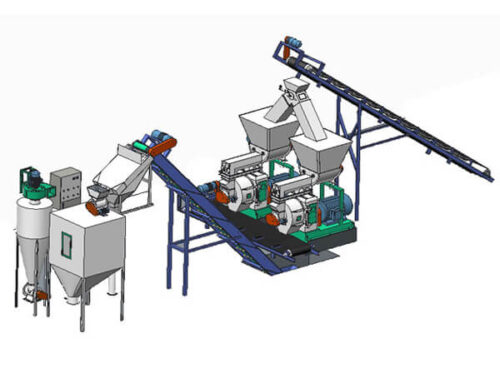

Sawdust pipe dryer is a good choice for drying biomass materials like sawdust, wood chips, wood shavings, bagasse, rice hulls etc. It is composed of air boiler, hopper, cyclone separator, air blower and drying column. With this small sawdust dryer, materials can be dried to the desired moisture content.

Features of Sawdust Flash Dryer

1.The flash dryer can be widely applied. Various biomass materials can be dried.

2. This drying machine performs well but sales at a lower price.

3. The requirement for materials to be dried should meet:

Moisture content: below 55% Size: less than 3mm

4. It is easy to install and maintain.

5. It consumes less energy and causes less noise.

Working Principle of Small Sawdust Dryer

The raw materials are fed into the dryer by the conveying device. Meanwhile, the heated air is driven into the dryer. Both the materials and the heated air will be fully blended and then they move forward inside the whole pipes due to the strong suction of the air blower. Then moisture will evaporate when the biomass materials go through the whole pipe. At last, dried materials are discharged.

Importance of Biomass Material Drying

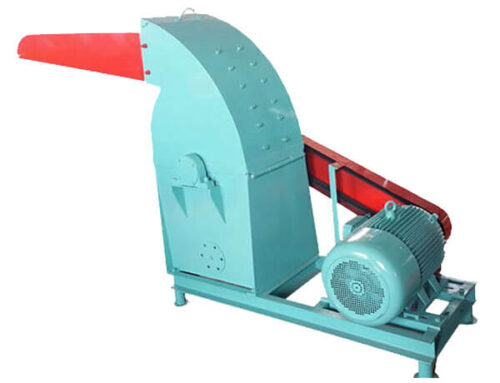

For production of biomass pellets and briquettes, the raw materials shall go through the following steps, i.e. grinding, drying, pelleting, cooling and packing in order. Hence, biomass drying is an important step for biomass pellets fuel production. Only the raw materials are dried until they are of the desired moisture content (generally 8%-15%), quality biomass pellets or briquettes can be produced.

Specification of Airflow Sawdust Dryer

| Model | TRM-QLHG22 | TRM-QLHG36 |

| Power | 5.5kw | 7.5kw |

| Capacity | 380—560kg | 500—700kg |

| Reduced Moisture | 10—15% | 15—25% |

Leave A Comment