Livestock Feed Hammer Mill Introduction

Feed hammer mill is mainly used to crush grain products like corn, wheat, sorghum, millet, soybean, yam, husk, etc. into powdery materials. Compared with other feed hammer mills, it is more energy efficient. This feed hammer mill is suitable for large and medium scale animal feed manufacturing factories and food processing industries.

Features of Livestock Feed Hammer Mill

1. Adopt advanced serpentine spring coupling and direct transmission.

2. Stable performance, strong and durable, beautiful appearance and simple operation.

3. Low consumption, high output and high efficiency.

4. The final products are in uniform fineness due to the reasonable arrangement of hammers and the clearance between hammers and screens.

5. Optional screen specifications; Quick opening door; Frame type screen pressing mechanism.

6. The screen mesh is fixed firmly, easy to exchange and convenient to operate.

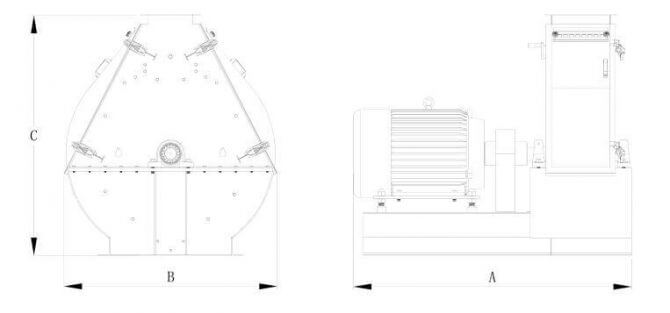

Livestock Feed Hammer Mill Appearance Size

|

|

Working Principle of Feed Hammer Mill

The major working part of hammer mill is rotor with hammer, which is at high speed when the raw material are putted into crushing chamber from the top of the feeding inlet, then raw materials are ground under the force of adjustable rotating hammers and friction between screen plates and gradually become small size particles. The small size particles, which is smaller than sieve pore, will discharged by centrifugal force and air flowing. While the bigger particles will be still left within the sieve and suffer from the strike from spinning hammer again until they become smaller.

Feed Hammer Mill Technical Parameters

| Model | ZW-29C | ZW-38C | ZW-50C | |||

| Rotor Diameter (mm) | 1120 | 1120 | 1120 | |||

| Spindle Speed (rpm) | 1480 | 1480 | 1480 | |||

| Linear Speed of Hammer (m/s) | 86.5 | 86.5 | 86.5 | |||

| Pulverizing Room Width (mm) | 290 | 380 | 500 | |||

| Number of Hammers | 48 | 64 | 96 | |||

| Mating Power (kw) | 55 | 75 | 90 | 110 | 132 | 160 |

| Normal Air Volume (m3/min) | 55 | 60 | 72 | 78 | 95 | 102 |

| Output (t/h) | 9 | 12 | 15 | 18 | 22 | 26 |