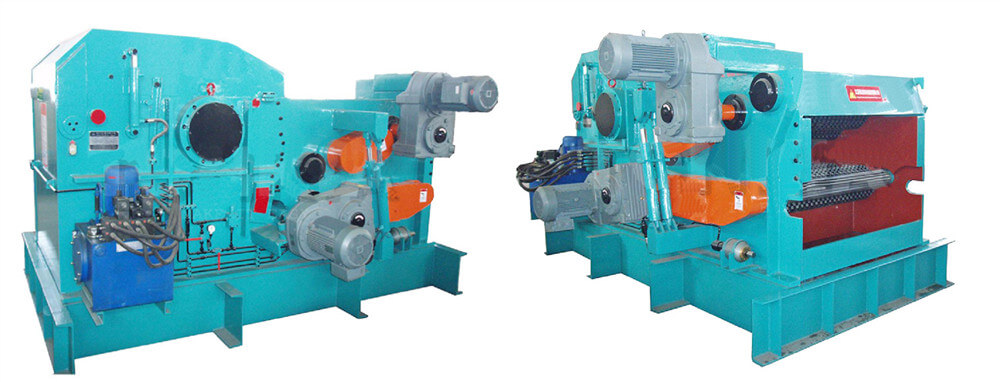

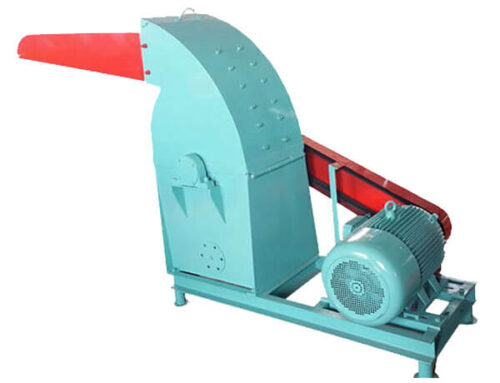

Introduction of Drum Wood Chipper

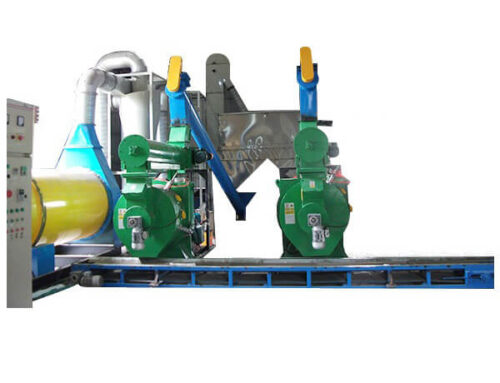

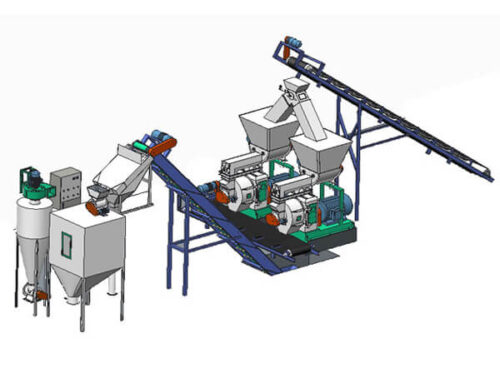

Drum wood chipper is used to chip raw materials into wood chips with uniform length, smooth incision and uniform thickness. Raw materials can be logs, branch wood, waste veneer, waste wood, bamboo wood, cotton stalk, reed stalk etc. Wood chips can be used for the raw materials of particle board, fiberboard and paper-making.

Drum wood chipper is a special equipment for the preparation of high quality wood chips. It is suitable for paper mill, particle board factory, fiberboard factory, production base and export base of wood chips.

Features of Drum Wood Chipper Machine

1. With compact structure, it can be operated easily.

2. It has wide application, because it can process various materials, like wood wastes and biomass residues.

3. Double rollers are adopted for our drum type wood chipper, so is works with high efficiency.

4. The wood chipper body is made of high strength steel, so it is firm, shock-resistant and causes less noise.

5. There are a series of screens for your choice. So it is able to help you to chip the raw materials into the desired size and thickness to satisfy your requirements.

6. With the hydraulic buffer system, the chipping machine can be simply maintained.

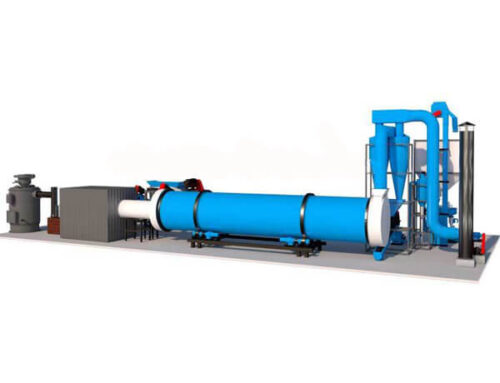

Components and Working Principle of Wood Chipping Machine

1. This drum type wood chipper is mainly composed of the machine body, knife roller, upper and lower feeding device and hydraulic system etc.

2. The raw materials is clamped and transmitted to the crushing chamber, then crushed by the rapidly-rotating blades on the roller. The larger wood chips will be processed for several times before discharging from the holes on the screen. At last, the wood chips are sent out of the cutting room by the high speed flow generated by cutting blades on the cutter head.

Technical Data of Drum Wood Chipper

| Model | PX15-80 | PX45-190 | GX215 | GX216 | GX218 | GX2113 |

| Capacity(t/h) | 0.8-1.2 | 2-4 | 3-4 | 5月8日 | 8-15 | 15-25 |

| Power(kw) | 30 | 45 | 45+2.2+1.5 | 55+3+1.5 | 110+5.5+1.5 | 160+7.5*2+1.5 |

| Material sizes before chipping(cm*cm) | 15*15 | 18*18 | 16*40 | 23*50 | 30*68 | 35*80 |

| Material sizes after chipping (mm) | 10-30 | 10-30 | 30 | 30 | 30 | 30 |

Leave A Comment