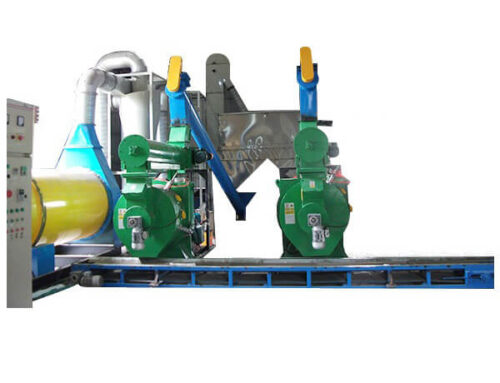

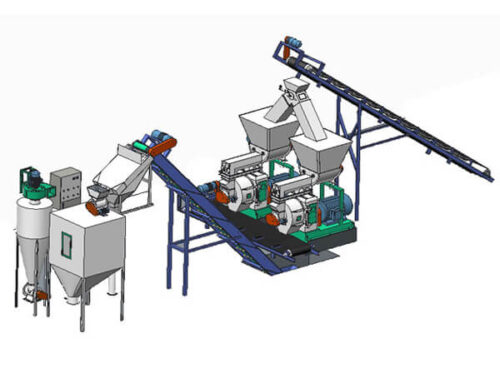

Electric Flat Die Wood Pellet Mill Introduction

Electric flat die wood pellet machine is an ideal choice for small-scale wood pellet production at home, on the farm, in the yard or outside in the open air. Driven by an electric motor, the flat die wood pellet press is more energy-saving and environmental-friendly. It is important to emphasize that pellets can be easily produced from various biomass wastes, like corn stover, sawdust, bagasse, rice husk, etc. The wood pellets can be used as fuel for heating, cooking, BBQ or animal bedding, cat litter, etc. The flat dies of our flat die wood pellet mill are of various diameters to meet your different application needs.

Electric Wood Pellet Mill Features

1. High capacity, low consumption, competitive price, small floor coverage and low failure rate make the flat die pellet machine economical and durable.

2. Small size makes it portable and convenient to move around.

3. Adopt screw center regulating structure, the clearance between rollers and flat die can be adjusted freely.

4. Adopt high precision gear transmission gearbox, ensuring reliable and efficient pelletizing process.

5. Equipped with quick disassembling type precisely-cast die clamp, able to change the new die and rollers fast and conveniently.

6. Both sides of flat dies can be used, so the service life is doubled.

7. Visible pelletizing process, easy to operate and maintain.

Wide Application of Electric Flat Die Wood Pellet Mill

1. It is suitable for crude fiber pelletizing, the raw materials can be agricultural and forestry wastes, like corn stover, wood chips, rice husk, cotton stalk, cotton seed hull, weed, etc.

2. It is also applicable for processing the materials with low cohesion rate or shaping rate, and pelletizing the biological bacterial fertilizer, organic fertilizer and compound fertilizer.

3. Flat die wood pellet mill is also good pelletizing equipment for animal bedding. Wood pellets can absorb up to 4 times their weight in moisture and ammonia to keep their house clean and fresh.

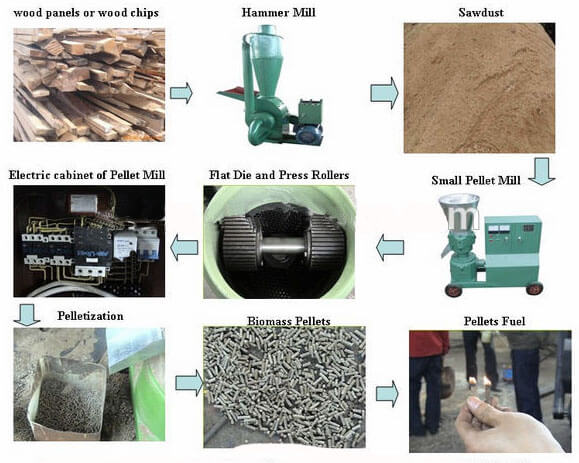

How Does the Electric Flat Die Wood Pellet Mill Work?

The flat die wood pellet mill is worked with rotating rollers and stationary flat die. The raw materials are fed into the feed hopper first, then fall down directly into the pelletizing chamber because of gravity. Under the effect of friction, the materials are compressed into the flat die holes. After shaping, the materials are squeezed out in the form of pellets. The rotating sharp cutter would immediately cut the exposed pellets into certain length.

Requirements of Raw Materials for Pelletizing

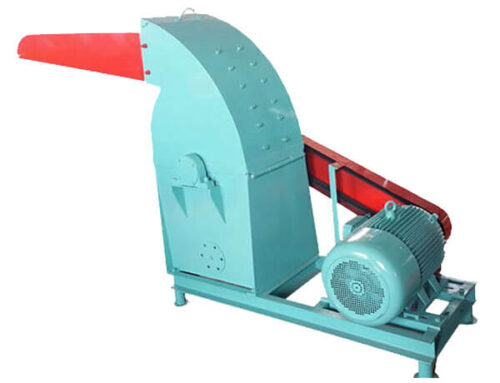

Size

Raw materials must be less than 6mm in size, otherwise a crushing machine is needed.

Moisture

Moisture is an essential factor that influences the final pellets quality. The most suitable moisture content for pelletizing is 12%-20%.

Purity

Some metal scraps or stones may contain in the biomass materials, which can damage the rollers and die. So the impurities should be removed before pelletizing.

Electric Flat Die Wood Pellet Mill Technical Data

| Model | Power(kw) | Capacity(kg/h) | Voltage | Flat Die Dia.(mm) | Dimension(mm) |

| PLM120 | 2.2 | 40-60 | Single phase:220V 50HZ Three phase:380V 50HZ |

120 | 550*300*710 |

| PLM200 | 7.5 | 110-140 | Three-phase:380V 50HZ | 200 | 850*420*850 |

| PLM300A | 15 | 220-280 | Three-phase:380V 50HZ | 300 | 1200*520*1050 |

| PLM300B | 18.5 | 250-300 | Three-phase:380V 50HZ | 300 | 1200*520*1050 |

| PLM350A | 22 | 300-360 | Three-phase:380V 50HZ | 350 | 1270*580*1150 |

| PLM400 | 30 | 400-500 | Three-phase:380V 50HZ | 400 | 1350*600*1200 |

| PLM500 | 55 | 700-800 | Three-phase:380V 50HZ | 500 | 1700*750*1450 |

| PLM600 | 90 | 1200-1300 | Three-phase:380V 50HZ | 600 | 2100*900*1650 |

| PLM700 | 132 | 1700-1800 | Three-phase:380V 50HZ | 700 | 2400*1050*1870 |

Leave A Comment