Introduction to Ring Die Feed Pellet Mill

Ring die feed pellet machine is designed for making crushed raw material into feed pellets. It is core and indispensable in feed pellet manufacturing process. It is with large capacity of 2-20t/h, suitable for medium or large feed processing factories.

Features of Ring Die Feed Pellet Mill

1.With multiple kinds of hole diameters, ring dies are optional, and the service life is long because of adopting high-quality craft dies.

2.Adopting excellent bearing, oil seal and air suction temperature-reducing system, this pellet machine is efficient, stable and low-noise.

3.For making high quality feed pellets, two or three jacket conditioners can be customized.

4.The main driving is equipped with high-precision gear drive. Compared with other belt drive, the output is improved about 20%.

5.In order to ensure the quality of discharged particles, the feeder uses variable frequency and variable speed motor.

6.The snakelike coupling has the features of high safety, compact structure, low fault rate and low noise, that is the international advanced compensation type.

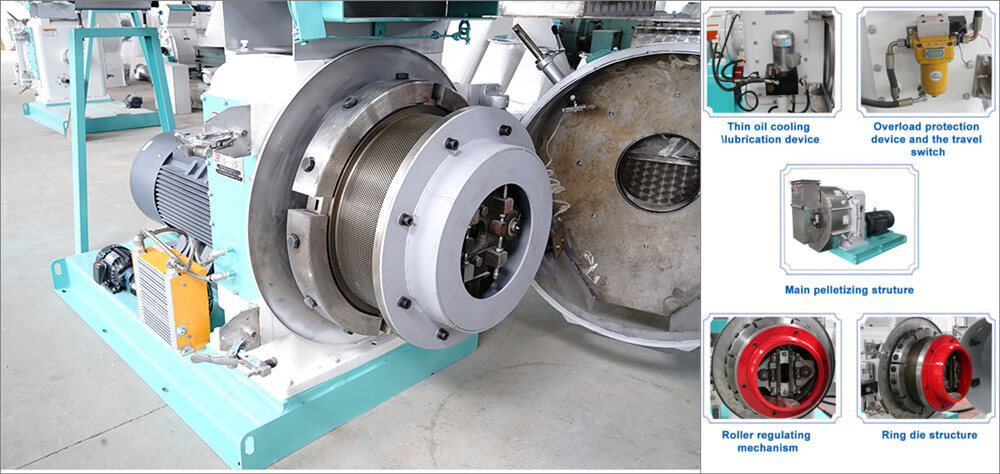

Ring Die Feed Pellet Mill Main Structure and Working Principle

1. This feed pellet machine mainly includes feeding system, conditioner device, pelletizing system, transmission system and lubrication system etc.

2. The raw materials with moisture no more than 15% are delivered into the screw feeder and get proper material flow through adjusting the feeding speed, then the material enter into conditioner where hot steam can offer favorable conditioning. During the process, you can also add oil or molasses ( additive contents of oil is no more than 3%). After the conditioning, the material temperature is about 64-85℃ and the moisture is 14-16%. And then the material enter into the pressing chamber. The feed materials are involved between the ring die and roller, two relatively rotating parts squeeze them into ring die holes. Feed pellets form in the mold holes, and are squeezed out of the holes’ outer ends. The pellets are cut into required length by the cutting knife.

Ring Die Feed Pellet Mill Technical Parameter

| Model | SZLH320 | SZLH350 | SZLH400 | SZLH420 | SZLH508 |

| Capacity(t/h) | 2-5 | 1.5-8 | 2-10 | 3-12 | 4月20日 |

| Main Power(kw) | 37 | 55 | 75/90 | 110 | 132/160 |

| Feeding Auger Power(kw) | 0.55 | 0.75 | 0.75 | 1.5 | 1.5 |

| Conditioner Power(kw) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Inner Diameter of Die(mm) | 320 | 350 | 400 | 420 | 508 |

| Die Speed(rpm) | 305 | 336 | 307 | 287 | 287 |

| Roller Outer Diameter(mm) | 140 | 165 | 190 | 206 | 222 |

| Dimension(mm) | 2300*1000*2100 | 3200*1100*1700 | 3200*1300*1900 | 3500*1300*2800 | 3500*1500*2900 |